- Home

- Special Services

MARINE SERVICES

construction

other services

weld services

- NDT Services

methods

additional services

- About Us

- Locations

Reliable Concrete Inspection Services

International Inspection performs concrete inspection services to help clients work safer and with improved effectiveness on the jobsite. Depending on the scope of the job, it may be necessary for employees to perform saw cutting or concrete coring to relieve expansion stress and allow passage for utility lines respectively. To do so blindly risks hitting unexpected obstacles such as rebar, or conduits or post tension cables, which can result in a host of negative consequences. Damage to equipment, cut electrical cables, and injury to workers can all result from encountering subsurface objects during coring or cutting. We provide concrete inspection services to ensure that work may proceed safely and unimpeded.

Our expert technicians perform two methods of concrete inspection, each of which offers their own variety of benefits:

X-ray Capabilities

The first method uses industrial film radiography techniques to generate detailed images of subsurface conditions in much the same process that yields medical x-ray scans. By aiming a powerful emitter — positioned opposite a sensitive detector — at a subject, our licensed technicians can render an outline of all ferrous and non-ferrous objects beneath the surface as if the surrounding concrete were not even present. We process all data on-location, producing interpretable results much faster than the industry-average wait time of 6 hours and eliminating the need for a follow-up visit to present the finished images.

The method has certain limitations however, as it requires technicians to have access to both sides of the concrete for analysis. Furthermore, the amount of radiation emitted during testing prohibits people without appropriate personal protective equipment (PPE) from coming within 40ft of the source from any direction. Thankfully, our alternative method of concrete scanning shores up the shortcomings associated with x-ray imaging.

Our X-ray Analysis Process

- Complete walkthrough of project upon arrival

- Determine North location and plan out the amount and locations of shots

- Verify x-y locations for ideal film placement using proprietary magnet and gauss meter, mark on bottom of slab

- Protect general public by setting up barriers at safe distances ensuring no radiation exposure

- Take x-rays at each previously determined location

- Process film in mobile darkroom

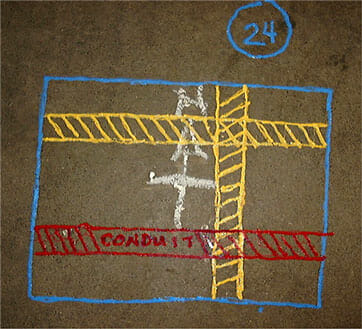

- Present findings and lay them out on the concrete itself

Layout/Report Example

Should your project require a report, our technicians can take digital photos of the project site and the radiograph. These experts will then provide a brief overview of the findings.

Radar Capabilities

Radar survey makes up the second branch of our concrete inspection services. By sending electromagnetic signals into the subject area and measuring the time it takes and the pattern in which they bounce back to the receptor, our equipment can determine the location and approximate depth of features beneath the surface. We can detect voids, ferrous and non-ferrous objects, and any other differences in material composition to an accuracy within 1”. This method requires access to only one of the concrete’s faces, allowing inspectors the flexibility to image subsurface conditions for slabs-on-grade or retaining walls, for example.

Additionally, the method is less disruptive to daily operations on the jobsite because it requires no safety clearance; the signals emitted by our radar equipment are not radioactive and thus not harmful to the general public. Because setup takes very little time and images are produced near instantly, overall technician work hours needed for initial testing and analysis of findings are significantly reduced. Each of these factors contributes to lowering the relative cost of this inspection method.

Radar Surveys are referred to with two different acronyms –

- Ground Penetrating Radar (GPR)

- Subsurface Interface Radar (SIR)

These two acronyms are manufacturer-defined and fundamentally refer to the same process. The equipment may vary slightly but the process is the same, and therefore the results will be the same.

Our Radar Survey Process

- Verify areas of interest upon arrival by performing complete walkthrough with client

- Determine if available scan area makes imaging possible/practical

- Set up equipment to perform “reconnaissance” scan to both calibrate the system and identify depth of concrete

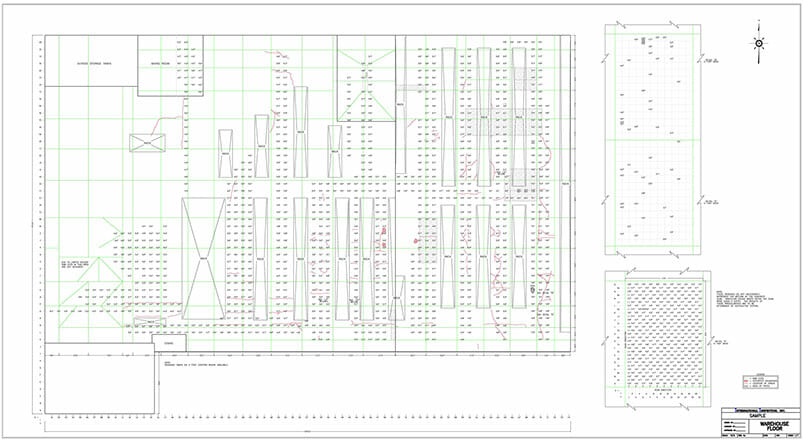

- If 3D scan is not requested/relevant, mark all indications found during recon with paint stick

- If using 3D scan, prepare area by placing grid sheet or snapping chalk lines as appropriate

- Acquire data using grid sheet

- Process data, reviewing 1” of depth at a time through entire slab

- Mark location of indications and approximate depth on grid sheet or slab as appropriate

Report Example

Should your project require a report we can either process and send the data in formal report format, email it to your desired contacts, or save the data to CD for your archives.

Ultimately, this method is not perfect either, as it does not produce images of the same quality that x-ray does. Our experts can help clients determine the most effective plan for inspecting subjects of interest using either one of the methods above or some combination of both as appropriate.

If your jobsite needs concrete inspection services provided by a highly qualified and experienced provider, contact International Inspection with your request today.